What is Centreless Grinding?

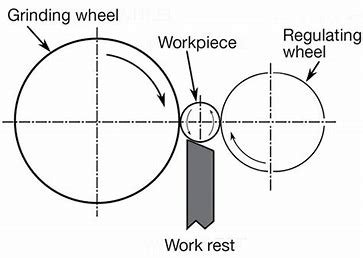

Centreless grinding is a cylindrical machining process that uses an abrasive cutting technique to remove material from a workpiece. There are 3 core elements to grinding, as demonstrated above in the diagram; Larger grinding wheel – Control wheel – a regulating wheel that controls the rotational speed, a slower pace which allows cut to be made, and Workblade – The part being machined is supported on the workblade that sits between the 2 rotating cylinders, it is the pressure of these 2 cylinders that hold the part in place.

Centreless grinding is a straightforward yet accurate process with more precise control over concentricity, size, and roundness. As there are limited moving parts involved, it is ideal for finishing the outside diameter of small cylindrical metal parts requiring tight tolerance. It is capable of performing at high speeds making the process more time-efficient, great for high-volume operations such as aerospace, automotive etc.